Your Cart

x

Timber

Explore our timber category, specially curated for garden fencing enthusiasts and professionals alike. Here, you will find an extensive range of timber products, designed to meet all your garden fencing needs. Our collection boasts premium-quality materials that ensure durability, reliability, and aesthetic appeal to enhance any garden space.

Whether you're undertaking a DIY project, revamping your garden, or conducting professional landscaping, our timber selection promises to cater to diverse preferences and requirements. Delve into our timber category and discover the perfect foundation for creating secure and stylish garden enclosures.

Subcategories

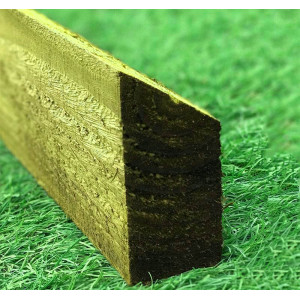

Introducing the 1.83m x 38x16mm Trellis Batten - the essential piece to elevate your garden today. Our pressure-treated brown battens are built with rough sawn material, providing an on-trend, rustic look.

Stand out in your neighbourhood with our unique selling proposition of durability and aesthet..

£1.09

Ex Tax:£0.91The standard 75mm x 32mm fence panel back rail can be nailed directly to the closeboard fence eliminating the need for specially cut posts to support it.High Pressure treated with Tanatone Brown (or similar), providing a 15 year service life when used above DPC and in accordance with approved trade ..

£3.29

Ex Tax:£2.743.6M x 100MM x 47MM is commonly known as 4x2inch, although the finished size is 95MM x 45MM it is still commonly known as 100MM x 47MM in the industry.Our 3.6M 4x2 is machined and regularised, which means the edges of the timber have been eased. Being regularised means the length of timber is s..

£11.95

Ex Tax:£9.96Fence panel caps are an important element to a traditional closeboard fence, extending the life by directing rain away from your fence.High Pressure treated with Tanatone Brown (or similar), providing a 15 year service life when used above DPC and in accordance with approved trade practiceAll of our..

£1.29

Ex Tax:£1.084.2M x 150MM x 47MM is commonly known as 6x2inch, although the finished size is 145MM x 45MM it is still commonly known as 150MM x 47MM in the industry.Our 4.2M 6x2 is machined and regularised, which means the edges of the timber have been eased. Being regularised means the length of timber is ..

£20.95

Ex Tax:£17.46100MM x 47MM Wallplate. All of our softwoods are responsibly sourcedIt is important that all cut ends are re-sealed with a proprietary treatment.Combined with other fencing components you can create strong and attractive traditional board fencing..

£7.95

Ex Tax:£6.63An alternative to the arris rail, the cant rail can be nailed directly to the closeboard fence eliminating the need for specially cut posts to support it.High Pressure treated with Green (or similar), providing a 15 year service life when used above DPC and in accordance with approved trade practice..

£6.95

Ex Tax:£5.792.4M x 100MM x 47MM is commonly known as 4x2inch, although the finished size is 95MM x 45MM it is still commonly known as 100MM x 47MM in the industry.Our 2.4M 4x2 is machined and regularised, which means the edges of the timber have been eased. Being regularised means the length of timber is s..

£7.95

Ex Tax:£6.634.2M x 100MM x 47MM is commonly known as 4x2inch, although the finished size is 95MM x 45MM it is still commonly known as 100MM x 47MM in the industry.Our 4.2M 4x2 is machined and regularised, which means the edges of the timber have been eased. Being regularised means the length of timber is s..

£13.95

Ex Tax:£11.63Introducing the 0.9m x 125x22mm 2EX Feather Edge Board – the ideal solution for creating stylish and durable feather edge cladding. This high-quality, pressure-treated timber board offers an attractive appearance and ensures long-lasting performance, perfect for your fencing or cladding needs.

The ..

£0.99

Ex Tax:£0.83Introducing the 1.8m x 125x22mm 2EX Feather Edge Board – the ideal solution for creating stylish and durable feather edge cladding. This high-quality, pressure-treated timber board offers an attractive appearance and ensures long-lasting performance, perfect for your fencing or cladding needs.

The ..

£1.89

Ex Tax:£1.58Introducing the 1.65m x 125x22mm 2EX Feather Edge Board – the ideal solution for creating stylish and durable feather edge cladding. This high-quality, pressure-treated timber board offers an attractive appearance and ensures long-lasting performance, perfect for your fencing or cladding needs.

The..

£1.79

Ex Tax:£1.49